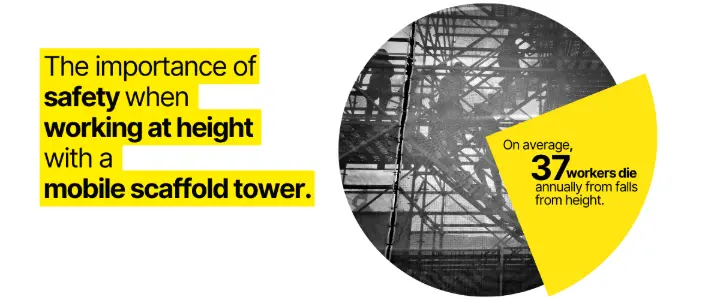

Scaffolds are essential for tasks requiring height access, offering versatility and efficiency. However, improper use can lead to serious accidents. Here are seven common mistakes to avoid to ensure safety and efficiency when using mobile scaffolds.

Contents;

1. Choosing the Wrong Scaffold Tower

2. Failing to Inspect and Secure the Tower

3. Skipping Proper Training

4. Ignoring Assembly Instructions

5. Using Improper Access Methods

6. Overloading the Scaffold

7. Operating in Adverse Weather Conditions

1. Choosing the Wrong Scaffold Tower:

Selecting the right mobile scaffold tower is crucial. Consider your project’s height, load requirements, and working environment. For quick, light-duty tasks, ladder towers are ideal, while stairway towers are better for continuous access. In electrically hazardous areas, fiberglass (FRP) scaffolds provide the safest option. Avoid settling for the wrong type, as it compromises functionality and safety.

Article: 5 Reasons to Avoid Mixing Scaffold Tower Components

2. Failing to Inspect and Secure the Tower:

One of the simplest yet most overlooked steps is inspecting the mobile scaffold before use. Check for damaged or loose parts, as faulty components can lead to catastrophic failures. Additionally, mobile scaffolds must be stabilized to avoid tipping. Use stabilizers or outriggers, and always lock the mobile scaffold wheels once the scaffold is positioned. Regular inspections and securing the tower ensure it remains steady and safe during use. These steps, though small, can significantly reduce risks and enhance overall stability on-site.

3. Skipping Proper Training:

Untrained personnel working on or assembling mobile scaffolds is a recipe for disaster. All employees must receive thorough training on mobile scaffold safety, including assembly, usage, and dismantling. Proper training equips workers with the knowledge to prevent mishaps and respond effectively to unexpected situations. Competency reduces the risk of errors and enhances overall workplace safety.

4. Ignoring Assembly Instructions:

Manufacturer’s instructions exist for a reason. Incorrect assembly often leads to structural issues and potential collapse. Always follow the provided guidelines to ensure the aluminium mobile scaffold is assembled correctly and functions as intended. Missteps during assembly not only waste time but can jeopardize the safety of all workers.

Article: Everything You Need to Know About Maintenance at Height

5. Using Improper Access Methods:

Climbing the scaffold from the outside is highly unsafe. Always use internal ladders or designated access points, such as the 3T (Through the Trapdoor) method. This practice minimizes the risk of falls and ensures a secure means of ascent and descent. Proper access methods are integral to preventing avoidable injuries.

Article: How Do You Ensure Your Scaffolding Is Safe to Use?

6. Overloading the Scaffold:

Mobile scaffolds have load limits for a reason. Overloading with materials or personnel can cause structural failure and accidents. Always adhere to the specified weight capacity to maintain safety and functionality. Remember, exceeding the load capacity not only endangers the structure but also compromises the safety of those working on and around it.

7. Operating in Adverse Weather Conditions:

High winds, heavy rain, or snow pose serious risks when working on mobile scaffolds. Postpone or pause work until conditions improve to avoid accidents caused by reduced stability or visibility. Weather-related risks are often underestimated, but exercising caution in such conditions can prevent costly incidents.

Final Thoughts:

By avoiding these common mobile scaffold mistakes, you can ensure a safer and more efficient work environment. Always prioritize proper training, regular inspections, and adherence to safety guidelines. Whether you’re using aluminium mobile scaffolds, portable scaffolds, or movable aluminium scaffolding, following these precautions will help you avoid costly errors and maintain productivity.

For high-quality mobile scaffolds, including aluminium mobile tower scaffolds, movable scaffolding platforms, and other access solutions, contact your trusted provider today. Your safety and project success depend on it!

Mobile scaffolds bring convenience and flexibility to various tasks. However, maintaining safety requires vigilance, proper training, and adherence to best practices. Taking the time to ensure everything is set up correctly and used safely can make a world of difference, both in terms of efficiency and protecting everyone on-site.

If you are looking for an access solution to prioritize safety, then check Y-Access Manufacturing’s range of work-at-heigh products. Our products are designed to provide superior protection while ensuring maximum durability and longevity. Don't compromise on safety, choose Y-Access Manufacturing for all your ladder needs.

Reach out to us at: sales@ymfg.co.in or call: +91-9015964626